Overview

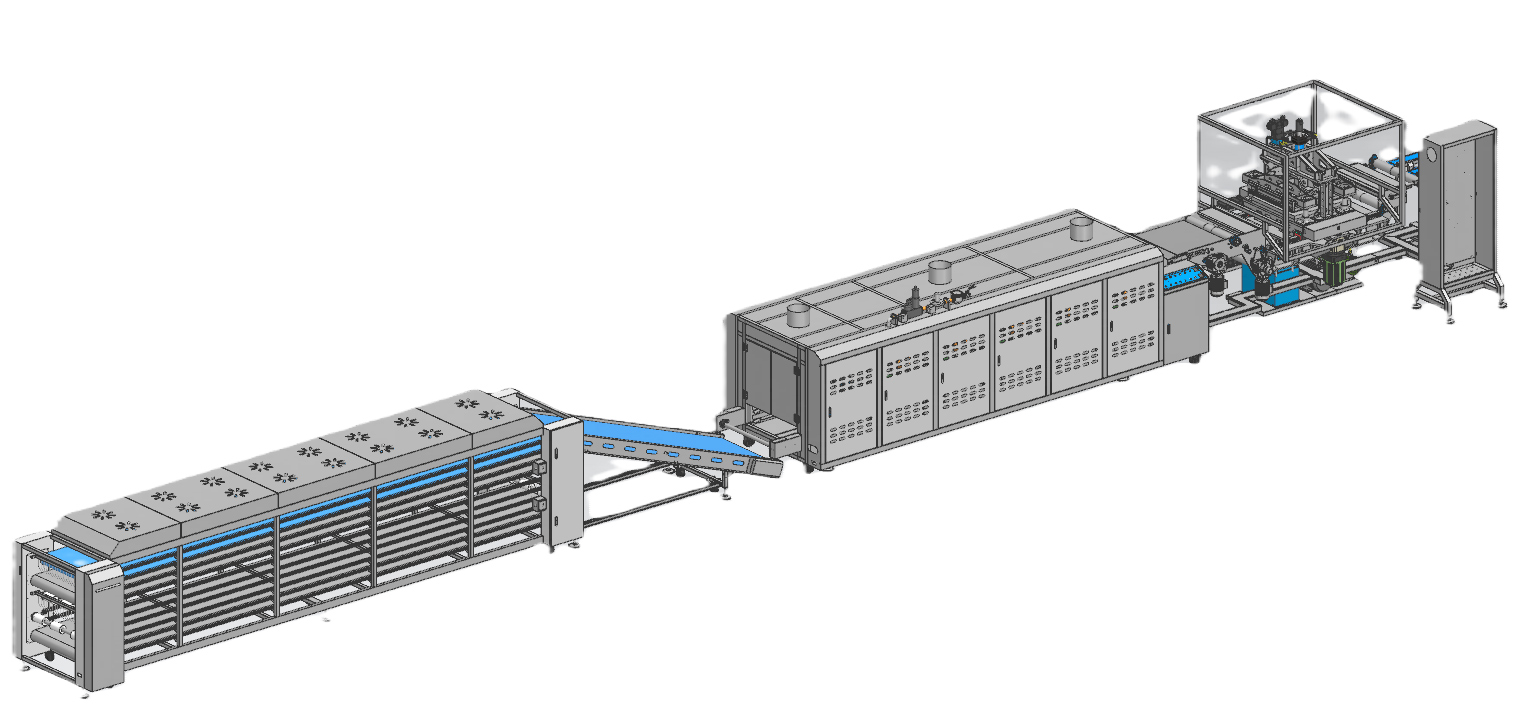

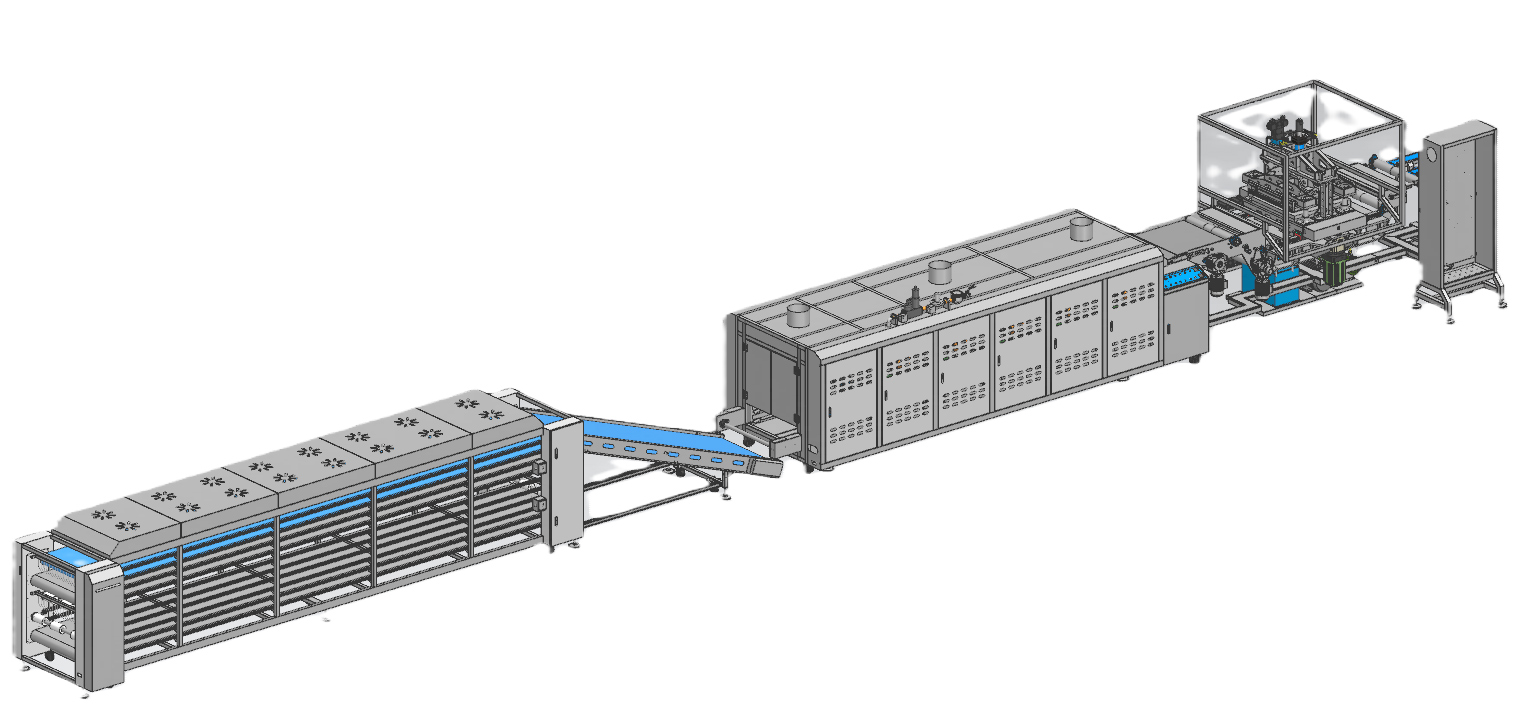

Featuring a fully integrated workflow from dough preparation to final packaging, the system eliminates manual bottlenecks and minimizes waste while accommodating high-speed production demands. Its adaptive technology ensures seamless transitions between different taco formats—from thin, flexible corn tortillas to thick, crunchy wheat shells—with adjustable parameters for dough thickness, forming pressure, and cooking intensity. Built with food-grade materials and compliance with international safety standards, this production line sets a new benchmark for reliability in commercial taco production.

Features

Dual-Mode Intelligent Forming System

Equipped with adaptive molds that automatically switch between soft tortilla flattening and crispy shell shaping via a single-touch interface, reducing changeover time to 3 minutes.

Servo-driven rollers with real-time thickness sensors (accuracy ±0.1mm) ensure uniform dough sheeting, critical for consistent cooking and structural integrity in both soft and fried tacos.

Energy-Efficient Hybrid Cooking Module

Combines infrared radiant heating for soft tortilla maturation (180°C–220°C) and a forced-convection oil bath with dynamic temperature regulation (200°C–240°C) for crispy shells, optimizing energy use by 30% compared to traditional systems.

Automated oil filtration system extends oil lifespan by 50%, reducing operational costs and environmental impact.

Smart Quality Assurance Suite

Vision-based inspection cameras detect defects like uneven browning, misshapen edges, or thickness variations, triggering automatic rejection with 99.8% accuracy.

Data logging software tracks key metrics (production speed, dough yield, energy consumption) for real-time process optimization and compliance reporting.

Modular Expandability

Customizable conveyor configurations (straight, L-shaped, or spiral) fit tight factory layouts, with optional add-ons for seasoning application, cheese melting, and pre-packaging garnish integration.

Quick-release dough hoppers and interchangeable cutting blades support rapid product diversification, ideal for producing specialty tacos with fillings or gluten-free variants.

User-Centric Control Interface

15-inch touchscreen HMI with intuitive recipe management, storing up to 100 taco profiles (dough type, cooking time, forming pressure) for instant recall.

Remote monitoring via IoT connectivity allows real-time diagnostics and firmware updates, minimizing downtime and enabling predictive maintenance.

Application

Industrial Snack ManufacturersIdeal for producing retail-packaged taco shells and tortillas in bulk, with scalable output ranging from 2,000–5,000 units per hour. The line’s precision ensures uniform sizing for automated filling and sealing in commercial packaging lines.

QSR Central KitchensProvides consistent pre-cooked tortillas and par-fried shells for quick-service chains, reducing on-site preparation time and ensuring brand-standard quality across all locations. Integrated cooling tunnels maintain product freshness during transit to stores.

Frozen Food ProducersPerfect for manufacturing frozen taco kits and pre-formed shells, with rapid cooling and freezing integration that preserves texture and crunch after reheating. Meets strict FDA and BRCGS standards for frozen food processing.

Specialty Food ExportersHandles diverse global taco variations, from Mexican-style corn tortillas to international fusion recipes (e.g., gluten-free, low-carb, or multigrain). Customizable seasoning modules allow regional flavor adjustments without hardware changes.

Faq

Q: What is the minimum dough moisture content the line can process?

A: The dough handling system accommodates moisture levels between 30–55%, suitable for both dry corn masa and high-hydration wheat doughs. Automatic humidity sensors adjust roller pressure to prevent sticking.

Q: Does the line support organic or non-GMO certifications?

A: Yes, all contact surfaces are made from USDA-certified organic-compliant materials, and the cleaning protocol includes validated sanitization cycles for allergen-free and organic production runs.

Q: Can the forming system handle filled tacos (e.g., stuffed shells)?

A: The standard line produces unfilled shells/tortillas, but optional stuffing modules can be integrated for filled tacos, with precision depositors ensuring uniform filling distribution and seal integrity.

Q: What is the noise level during operation?

A: The line operates at ≤75 decibels thanks to sound-insulated motors and vibration-dampening mounts, compliant with OSHA workplace noise regulations for 8-hour shifts.

Q: How does the IoT feature benefit maintenance?

A: The remote monitoring system alerts operators to potential issues (e.g., blade wear, temperature fluctuations) before they cause downtime. Historical data analysis predicts component lifespans, optimizing replacement schedules.

| Model | JKMXGB-720 | Power | 70kw |

| Size | 21000×1555×2080mm | Capacity | 6inch:6000-8000 pcs/h 8inch:3000-4000 pcs/h 10inch:3000-4000 pcs/h

|