Overview

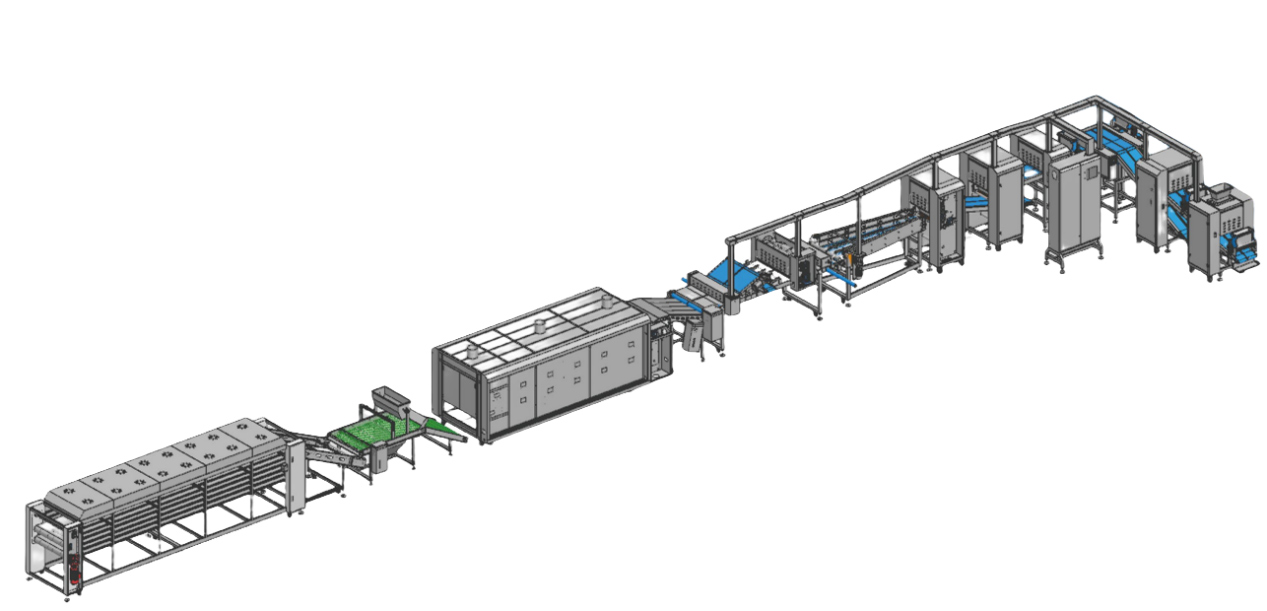

The Auto feeding High Accurancy High Performance Roti Production Line is a state-of-the-art solution designed to revolutionize the production of rotis, a traditional flatbread popular in many parts of the world. This production line is built to deliver exceptional accuracy, performance, and efficiency, making it the ideal choice for commercial kitchens, food processing plants, and large-scale roti manufacturers.

The auto-feeding system ensures a continuous and precise supply of dough, eliminating manual intervention and reducing the risk of human error. The line is equipped with advanced technology that allows for precise control over every stage of the roti-making process, from dough portioning to rolling, cooking, and stacking. This results in rotis that are uniform in size, thickness, and quality, ensuring customer satisfaction and repeat business.

Features

Automatic Dough Feeding and Portioning: The production line features a highly accurate dough portioning system that uses advanced sensors and algorithms to divide the dough into consistent portions. The auto-feeding system then delivers these portions to the rolling station, ensuring a steady and reliable supply of dough.

High-Accuracy Rolling Mechanism: The rolling station is equipped with precision rollers that shape the dough into perfectly round rotis with the exact thickness specified. The rollers are made from high-quality materials that are resistant to wear and tear, ensuring long-lasting performance and consistent results.

High-Performance Cooking System: The cooking section of the line uses advanced heating technology to cook rotis quickly and evenly. The temperature and cooking time can be adjusted to meet the specific requirements of different types of rotis, whether they need to be soft and fluffy or slightly crispy.

Automatic Stacking and Packaging: At the end of the production line, an automatic stacking system neatly piles the cooked rotis, and a packaging system can be integrated to wrap them for distribution. This reduces labor costs and ensures that the rotis are handled hygienically and efficiently.

Intelligent Control System: The entire production line is controlled by an intelligent system that allows operators to monitor and adjust the process parameters from a central control panel. The system also provides real-time data on production output, energy consumption, and quality control, enabling businesses to make data-driven decisions to optimize their operations.

Application

The Auto feeding High Accurancy High Performance Roti Production Line is suitable for a variety of commercial applications, including:

Roti Manufacturers: Large-scale roti producers can rely on this line to meet the high demand for rotis in the market. The line's high accuracy and performance ensure that they can produce large quantities of rotis with consistent quality, reducing waste and increasing profitability.

Quick Service Restaurants (QSRs): QSRs that serve rotis as part of their menu can benefit from the line's ability to produce rotis quickly and efficiently, ensuring that they can meet the demands of their customers during peak hours.

Catering Services: Catering companies that need to produce a large number of rotis for events and functions can use this line to streamline their production process, saving time and labor costs while delivering high-quality rotis.

Frozen Food Industry: The line can be used to produce rotis for the frozen food market, ensuring that the rotis maintain their quality and texture after freezing and reheating. The accurate portioning and uniform cooking help to meet the strict standards of the frozen food industry.

Faq

Q: How accurate is the dough portioning system?

A: The dough portioning system is highly accurate, with a variation of less than 1% in portion weight. This ensures that each roti is of consistent size and quality.

Q: Can the line be adjusted to produce different sizes of rotis?

A: Yes, the line can be easily adjusted to produce rotis of different diameters and thicknesses by simply changing the settings on the control panel. This makes it a versatile solution for businesses that produce multiple sizes of rotis.

Q: What is the energy consumption of the production line?

A: The energy consumption depends on the model and configuration of the line. Our team can provide you with detailed energy usage data based on your specific requirements, and we design our lines to be as energy-efficient as possible.

Q: How long does it take to set up and start producing rotis with this line?

A: The setup time varies depending on the complexity of the line, but our team of technicians will install and commission the line for you, providing training to your staff to ensure that you can start producing rotis quickly and efficiently.

| Model | JKRTB | Power | 25KW |

| Size | 28,300 x5,800 x1830 mm | Capacity | 8000-10000 Pcs/H |