Overview

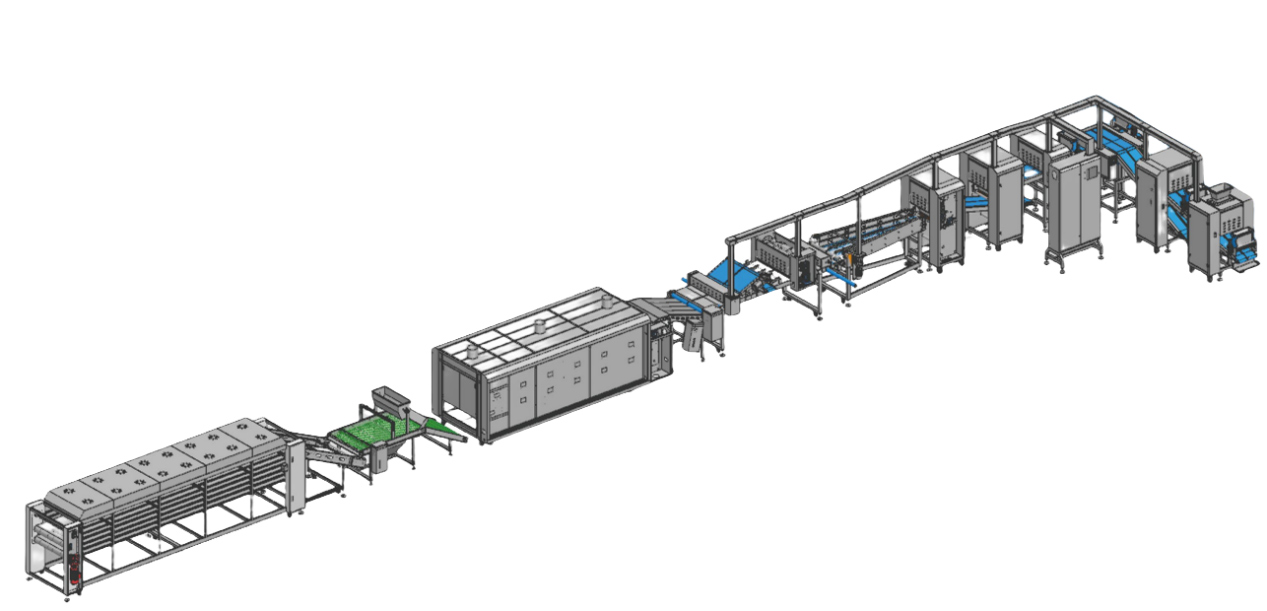

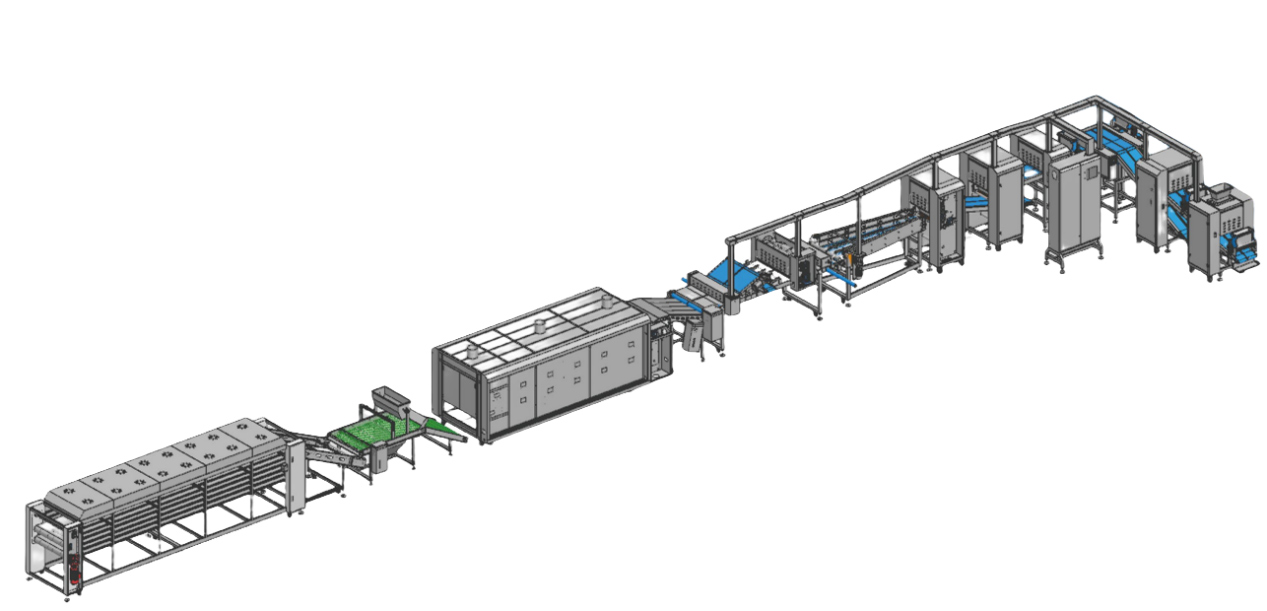

The Gravity Feed Professional Chapati Production Line for Commercial is a comprehensive solution designed to automate the production of chapatis, a popular flatbread in many cuisines. This production line combines efficiency, precision, and reliability to meet the high demands of commercial kitchens, restaurants, and food production facilities.

The gravity feed system ensures a continuous and consistent supply of dough, eliminating the need for manual feeding and reducing labor costs. The line includes several stages, from dough preparation to final cooking, all integrated into a seamless process. Each component of the production line is designed to work together harmoniously, ensuring that chapatis are produced with uniform thickness, size, and texture, while maintaining the authentic taste and quality that customers love.

Features

Gravity Feed Dough Supply: The innovative gravity feed system automatically delivers dough to the rolling and shaping stations, ensuring a steady and even flow. This reduces the risk of dough blockages and ensures consistent portioning, resulting in uniform chapatis.

Precision Rolling and Shaping: The line features high-quality rollers that shape the dough into thin, round chapatis with precise thickness. The rollers are adjustable, allowing operators to set the desired thickness for different types of chapatis, from thin and crispy to thick and fluffy.

High-Speed Cooking: The cooking section of the production line is equipped with efficient heating elements that cook chapatis quickly and evenly. The temperature can be adjusted to achieve the perfect level of browning and texture, whether the chapatis are meant to be soft and pliable or slightly crispy.

Automatic Quality Control: The line includes sensors and cameras that monitor the chapatis at each stage of production, ensuring that only high-quality products move to the next stage. Any defects, such as uneven thickness or improper shaping, are detected and removed automatically, reducing waste and improving product consistency.

Easy to Operate and Maintain: The production line is designed with a user-friendly interface that makes it easy for operators to set up and control the process. The modular design allows for easy access to each component, making maintenance and cleaning straightforward and minimizing downtime.

Application

The Gravity Feed Professional Chapati Production Line is suitable for a wide range of commercial applications, including:

Restaurants and Catering Services: Restaurants that serve chapatis as a staple can benefit from the high production capacity and consistent quality of this line, ensuring that they can meet the demands of their customers efficiently.

Food Production Facilities: Large-scale food producers can use this line to manufacture chapatis for retail sale, either fresh or frozen. The line's ability to produce large quantities of chapatis with uniform quality makes it ideal for meeting the needs of the market.

Canteens and Institutional Kitchens: Schools, hospitals, and other institutions that serve meals in large quantities can rely on this production line to produce chapatis quickly and cost-effectively, ensuring that meals are served on time and to a high standard.

Export Markets: For businesses looking to export chapatis to international markets, the production line's consistent quality and compliance with food safety standards make it an excellent choice for meeting the strict requirements of global markets.

Faq

Q: What is the production capacity of the Gravity Feed Chapati Production Line?

A: The production capacity varies depending on the model and configuration of the line. Our standard lines can produce between 500 and 2000 chapatis per hour, and we can also design custom lines for higher capacities.

Q: Can the line be used to produce other types of flatbreads, such as tortillas or naan?

A: Yes, the line can be adjusted to produce different types of flatbreads by changing the roller settings and cooking parameters. This makes it a versatile investment for businesses that produce multiple types of flatbreads.

Q: What type of dough does the line require?

A: The line is designed to work with standard chapati dough, which typically consists of wheat flour, water, and a small amount of salt. It can also handle doughs with minor variations, such as the addition of herbs or spices.

Q: Is the line compliant with food safety standards?

A: Yes, all components of the production line are made from food-grade materials and are designed to meet international food safety standards, such as FDA and CE requirements.

| Model | ZBSKXB | Power | 14KW |

| Size | 14,000 x3,000 x2330 mm | Capacity | 5000-9000 Pcs/H |