Ever wondered what makes a perfect pizza crust? Pizza dough rolling machine could be the secret! Choosing the right machine is crucial for achieving consistent dough quality. In this post, you'll learn about professional and home models, their features, and how they cater to different needs.

Understanding Professional Pizza Dough Rolling Machines

Features of Professional Machines

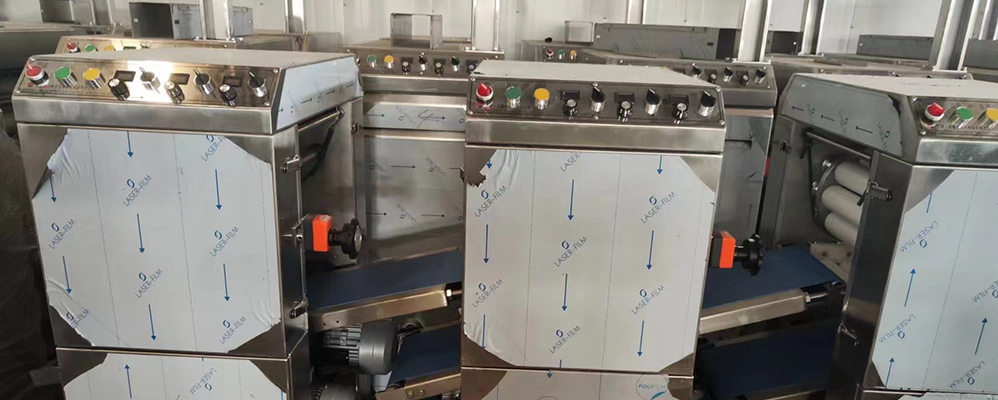

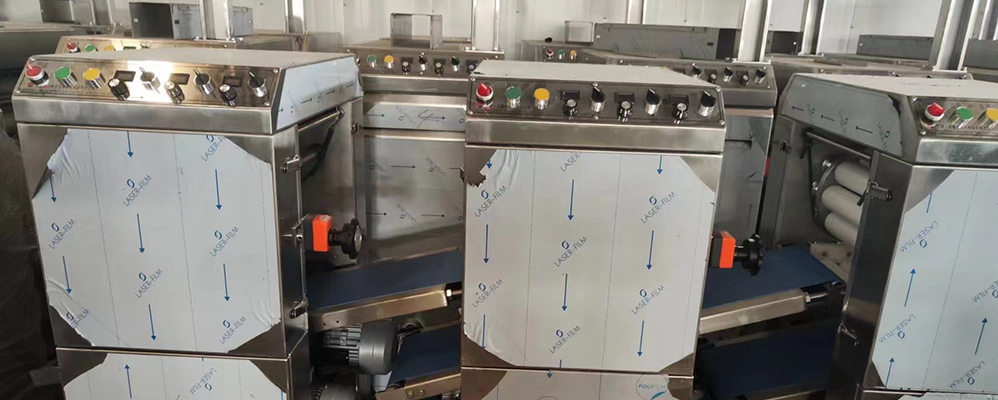

Professional pizza dough rolling machines are built tough for heavy-duty use. They often feature robust stainless steel construction, ensuring durability and easy cleaning. These machines come with wide rollers, typically between 16 to 24 inches, to handle large dough balls effortlessly. Adjustable thickness settings let operators customize dough thickness precisely, which is essential for meeting different pizza styles or dough recipes.

Many professional models include automatic feeding and rolling mechanisms, reducing manual labor and speeding up production. Safety features like emergency stop buttons and protective covers are standard, keeping operators safe during busy shifts. Some machines also offer programmable settings, allowing consistent dough rolling at the touch of a button.

Benefits for High-Volume Production

The main advantage of professional dough rolling machines lies in their ability to handle high volumes efficiently. They can process dozens or even hundreds of dough balls per hour, making them ideal for busy pizzerias, bakeries, or food service operations.

These machines help maintain uniform dough thickness and size, which improves product consistency and customer satisfaction. By automating the rolling process, they reduce labor costs and minimize physical strain on staff. This efficiency allows kitchens to meet demand during peak hours without sacrificing quality.

Moreover, professional machines often handle a variety of dough types, including thick, sticky, or high-hydration doughs, thanks to powerful motors and adjustable rollers. This versatility supports diverse menu offerings and recipe experimentation.

Examples of Professional Models

Several professional pizza dough rolling machines stand out for their performance and reliability:

Kemplex SF500SM Dough Sheeter: Known for its powerful motor and wide rollers, perfect for large-scale pizza production and pastry doughs. It offers precise thickness control and a compact footprint for commercial kitchens.

GGF EASY 500 SM Dough Sheeter: Combines speed and ease of use with adjustable settings. It’s popular among bakeries that require consistent dough sheeting for various products.

Infernus ITDR-16 Dough Roller: A budget-friendly yet rugged machine designed for pizza shops needing reliable dough flattening with adjustable thickness.

Sammic DF-40 Dough Roller: Built for high throughput, featuring stainless steel parts and adjustable rollers for consistent pizza bases.

Hosty DL40 Double Dough Roller: Features twin rollers for doubling output, ideal for operations with high pizza volume demands.

These examples illustrate the range of options available, from compact tabletop models to larger floor-standing units. Choosing the right model depends on production volume, space, and specific dough requirements.

Exploring Home Pizza Dough Rolling Machines

Features of Home Machines

Home pizza dough rolling machines are designed with simplicity and convenience in mind. They tend to be more compact and lightweight than professional models, making them easy to store and move around in a typical kitchen. Most home machines feature rollers between 8 to 12 inches wide, suitable for preparing dough for small to medium-sized pizzas.

Adjustability is a key feature, allowing users to set the dough thickness to their preference, whether for thin-crust or thicker styles. Many home models operate manually, using a hand crank, but electric versions with automatic rollers are also available for added ease.

Materials often include food-grade plastic or stainless steel components, ensuring hygiene and durability. Safety features such as protective covers and non-slip feet are common to prevent accidents during use.

Additionally, home machines usually focus on straightforward controls without complex programming, making them user-friendly for beginners or casual pizza makers.

Advantages for Small-Scale Use

Home dough rolling machines offer several benefits for small-scale pizza preparation:

Space Efficiency: Their compact size fits well in limited kitchen spaces, including countertops or small cabinets.

Affordability: Home models are generally much less expensive than commercial machines, making them accessible for hobbyists or families.

Ease of Use: Simple setup and operation mean anyone can roll dough consistently without extensive training.

Portability: Lightweight design allows easy transport for events like picnics or parties.

Reduced Labor: Rolling dough by hand can be tiring and inconsistent; these machines save effort and produce uniform results.

Customization: Adjustable thickness settings help home cooks experiment with different pizza styles and textures.

Maintenance: Cleaning tends to be straightforward, often involving removable parts that are dishwasher safe.

Popular Home Models

Several home pizza dough rolling machines have gained popularity for their performance and value:

Infernus ITDR-12 Dough Roller: A compact electric model with adjustable rollers, offering consistent dough thickness for personal pizza sizes. It balances affordability and durability.

Hosty Manual Dough Roller: A hand-cranked machine ideal for beginners who prefer manual control. It’s lightweight and easy to clean.

Sammic Mini Dough Roller: Designed for small kitchens, this model features stainless steel parts and simple thickness adjustments. It’s great for families who make pizza regularly.

KitchenAid Pasta Roller Attachment: Though primarily for pasta, many home cooks use this versatile attachment to roll pizza dough evenly when paired with a KitchenAid stand mixer.

Manual Dough Sheeter Tabletop Models: These offer a simple, compact solution for rolling dough flat, suitable for occasional pizza makers.

Each model suits different needs, from casual use to more frequent pizza-making enthusiasts. When choosing, consider factors like kitchen space, frequency of use, and desired dough thickness control.

Key Differences Between Professional and Home Machines

Capacity and Output

Professional pizza dough rolling machines are built to handle large volumes. They can process dozens, sometimes hundreds, of dough balls every hour. This high capacity suits busy pizzerias or bakeries where demand is constant and fast. Their wide rollers and powerful motors make quick work of big batches, reducing wait times and labor costs.

Home machines, in contrast, focus on smaller batches. They typically manage dough for a few pizzas at a time, ideal for families or casual pizza makers. Their rollers are narrower, often between 8 to 12 inches, limiting how much dough they can flatten at once. While slower than professional models, home machines still save effort and produce consistent results for everyday use.

Precision and Consistency

Precision is key in professional settings. Commercial machines offer fine-tuned thickness controls and programmable settings. This ensures every pizza base matches exact specifications, crucial for quality control and customer satisfaction. Their automated feeding and rolling systems maintain uniform dough thickness and size, batch after batch.

Home machines provide adjustable thickness too, but usually with simpler controls. They rely more on manual input, such as hand cranks or basic electric rollers. While they deliver good consistency for personal use, they don’t match the repeatability or precision of professional equipment. For home cooks, this level of control is often sufficient and easier to manage.

Ease of Use and Setup

Professional machines require a bit more setup and space. They often need dedicated counter or floor space and may involve more complex assembly or electrical connections. Operating them might require training, especially for models with programmable features. However, once set up, they streamline production and reduce manual labor significantly.

Home machines prioritize simplicity. They are compact, lightweight, and designed for easy setup on kitchen counters. Many are manual, needing no power source, while electric models plug into standard outlets. Their straightforward controls make them accessible to beginners and casual users. Cleaning and maintenance are usually quick, with removable parts and simple designs.

Factors to Consider When Choosing a Pizza Dough Rolling Machine

Choosing the right pizza dough rolling machine depends on several important factors. These help ensure the machine fits your needs and kitchen setup perfectly.

Production Needs and Volume

First, think about how much dough you need to roll daily. If you run a busy pizzeria or bakery, a professional machine with high capacity makes sense. These machines handle dozens or hundreds of dough balls per hour, keeping up with demand during peak times. They often have features like automatic feeding and programmable settings to maintain speed and consistency.

For smaller operations or home use, a compact machine is better. Home models work well for rolling dough for a few pizzas at a time. They save effort and deliver consistent thickness but aren’t built for continuous heavy use. Knowing your production volume helps you decide between a commercial-grade or home-use machine.

Budget Considerations

Budget plays a big role in your decision. Professional machines come with a higher price tag due to their durability, power, and advanced features. However, they can save money long term by reducing labor costs and improving efficiency.

Home machines are more affordable and still improve dough rolling compared to doing it by hand. They offer good value for casual pizza makers or small businesses starting out.

It’s smart to look beyond initial cost. Consider maintenance expenses, energy use, and expected lifespan. Investing in a reliable machine can reduce repairs and downtime, saving money over time.

Space and Kitchen Layout

Space availability is often overlooked but critical. Professional machines tend to be larger, requiring dedicated counter or floor space. Make sure your kitchen can accommodate the machine comfortably without disrupting workflow.

Home dough rollers are designed to be compact and portable. They fit easily on countertops or in cabinets, ideal for smaller kitchens.

Also consider ease of installation. Some commercial machines need special electrical connections or professional setup. Home models usually plug into standard outlets and require minimal assembly.

Benefits of Using a Pizza Dough Rolling Machine

Time and Labor Efficiency

Using a pizza dough rolling machine saves a lot of time and effort compared to rolling dough by hand. These machines quickly flatten dough balls to the desired thickness, cutting down prep time significantly. For busy kitchens, this means faster pizza production and shorter wait times for customers.

They also reduce physical strain on staff. Rolling dough by hand can be tiring, especially when making many pizzas in a row. A machine takes over the repetitive work, letting workers focus on other tasks. This boosts overall kitchen productivity and keeps the team fresh during busy shifts.

Consistency in Dough Thickness

One of the biggest challenges in pizza making is achieving uniform dough thickness. Variations can affect cooking times and texture, leading to inconsistent pizza quality. Dough rolling machines address this by providing precise, adjustable settings to control thickness exactly.

Once set, the machine produces dough sheets that are consistent every time. This uniformity helps maintain product quality and customer satisfaction. Whether you want thin-crust or thick, chewy bases, the machine ensures each pizza starts with the right foundation.

Enhanced Dough Quality

Rolling dough evenly improves its texture and structure. Machines apply consistent pressure across the dough, preventing thin spots or uneven stretching. This results in better gluten development and a more uniform crumb in the baked pizza.

Some machines also handle dough gently, preserving air bubbles that contribute to a light, airy crust. Others accommodate different dough types, including sticky or high-hydration recipes, without tearing or sticking.

Using a machine can also reduce the risk of overworking dough, which can happen with manual rolling. Overworked dough tends to be tough and less enjoyable. A rolling machine helps maintain the dough’s ideal elasticity and softness, enhancing the final pizza experience.

Conclusion

Professional pizza dough rolling machines excel in capacity and precision, ideal for high-volume production. Home machines offer simplicity and affordability, perfect for casual use. When choosing, consider your dough volume, budget, and space. Anhui Jinke Foodstuff Machinery Co., Ltd. provides reliable machines that enhance efficiency and dough quality. Investing in the right machine supports long-term success in pizza making, catering to both commercial and home needs.

FAQ

Q: What are the main benefits of using a pizza dough rolling machine?

A: They save time, reduce labor, ensure consistent dough thickness, and enhance dough quality.

Q: How do professional and home dough rolling machines differ?

A: Professional machines handle higher volumes with precision, while home machines are compact and user-friendly.

Q: What factors should I consider when choosing a dough rolling machine?

A: Consider production volume, budget, and available space.