Are you tired of inconsistent dough thickness ruining your baked goods? Achieving uniform dough thickness is crucial for perfect results every time. A roller machine for dough is the key to consistency, saving both time and effort.

In this post, we'll explore why a roller machine is essential, how it helps streamline your dough preparation, and how to choose the right one for your needs.

What is a Dough Roller Machine?

A dough roller machine is designed to flatten dough to a consistent thickness. It simplifies the process of dough preparation, which can otherwise be time-consuming and inconsistent. By using rollers, the machine applies even pressure, ensuring uniformity in every sheet of dough, whether you're preparing pizza crust, pastry, or bread.

Benefits of Using a Roller Machine for Dough

Time and Labor Savings

● Reduced Manual Labor: Roller machines take the physical effort out of dough preparation. Instead of rolling dough by hand, which can be tiring, the machine flattens it quickly and uniformly.

● Speeding Up the Process: A roller machine can save hours each week in a bakery or home kitchen, especially when preparing large batches. This significantly boosts efficiency.

● Labor Cost Reduction: In commercial kitchens, faster dough preparation translates to reduced labor costs, making the business more profitable.

Consistency and Uniformity

● Eliminating Human Error: A roller machine ensures dough is evenly rolled, removing the inconsistencies that come with manual rolling.

● Perfect Thickness Every Time: Whether for pizza, pastry, or bread, the machine guarantees uniform thickness, which is essential for consistent baking.

● Impact on Product Quality: Consistent dough leads to evenly baked products, improving texture, appearance, and taste.

Improved Product Quality

● Even Baking: Consistent dough thickness ensures uniform baking, preventing overcooked or undercooked spots.

● Better Texture: In products like pastries, even dough creates the desired flaky texture. For bread, it promotes a consistent rise and crumb.

● Enhanced Appearance: With even dough, products look professional and uniform, increasing customer satisfaction.

Versatility

● Multiple Dough Types: Roller machines can handle different types of dough, including pizza, pastry, pasta, and bread. This flexibility makes them ideal for bakeries that offer a wide variety of products.

● Diversifying Product Offerings: A single roller machine allows bakeries to produce multiple items, reducing the need for separate equipment and expanding their menu options.

Why is Uniform Dough Thickness Important?

Consistency in Baking

When dough is rolled to a consistent thickness, it bakes more evenly. This is crucial for avoiding areas that are overcooked or undercooked. For instance, pizza crusts with uneven thickness can result in some parts being crispy while others remain soggy. In pastries like croissants, uniform thickness ensures that all layers cook at the same rate, creating the delicate, flaky texture that’s highly sought after. For bread, consistent dough thickness supports a steady rise and even baking, preventing uneven texture in the finished loaf.

Impact on Product Quality

The texture, rise, and appearance of baked goods are directly influenced by how evenly dough is rolled. In products like pastries, even dough thickness is key to creating those beautiful, light layers that make them melt in your mouth. For bread, uniform dough ensures an even rise, leading to a more consistent texture throughout the loaf. When dough thickness varies, certain parts may rise more than others, resulting in an uneven texture and appearance. So, achieving uniform dough thickness is essential for producing high-quality, visually appealing baked goods.

Types of Roller Machines for Dough

Manual Dough Rollers

Manual dough rollers are simple, affordable machines ideal for small operations. They require you to roll dough by hand, giving you full control over the thickness. These machines are perfect for home bakers or small businesses with low production volumes. While they are cost-effective and easy to maintain, manual rollers can be time-consuming and require more physical effort, making them less efficient for larger batches.

Semi-Automatic Dough Rollers

Semi-automatic dough rollers offer a combination of motor assistance and manual control, making them a great choice for mid-sized bakeries. They provide a balance of speed and control, as the machine helps with the rolling process but still allows adjustments for thickness. These machines are faster than manual rollers and more efficient, making them ideal for businesses that need to increase production without sacrificing precision.

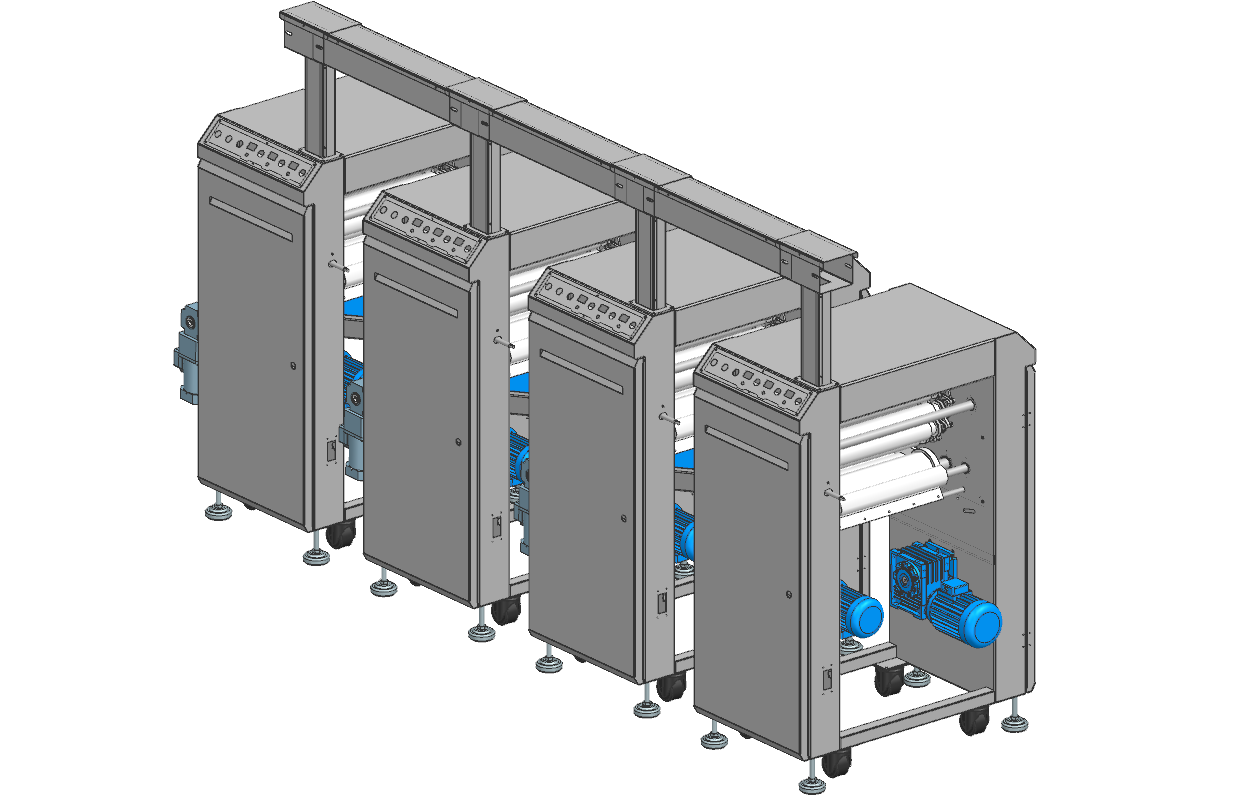

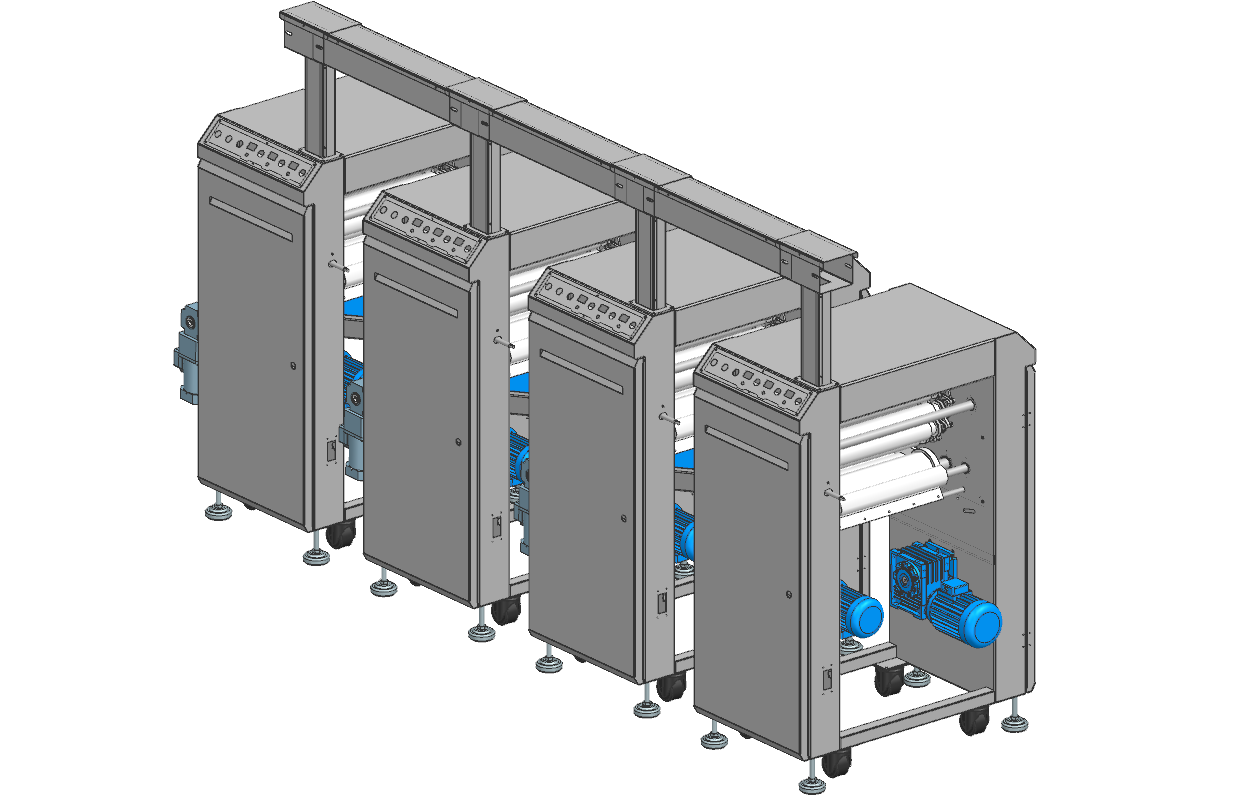

Fully Automatic Dough Rollers

Fully automatic dough rollers are designed for high-volume production environments. They handle the entire process automatically, from feeding dough to adjusting the thickness. These machines save significant time and improve efficiency, making them perfect for large bakeries or pizzerias where quick and consistent results are essential. Fully automatic models reduce labor costs and streamline the dough preparation process.

Key Features to Look for in a Roller Machine for Dough

Adjustable Thickness Settings

When choosing a dough roller machine, precise thickness controls are essential. Different dough types, such as pizza, pastry, or bread, require varying thicknesses. A machine with adjustable settings ensures you can customize the dough to suit your specific needs, whether you're making thin pizza crusts or thick pastry layers. By fine-tuning the machine, you can achieve consistent results every time, enhancing the quality of your baked goods.

Durability and Build Quality

The durability of the dough roller machine is vital, especially for businesses that rely on it daily. Machines made of high-quality materials, like stainless steel, offer longevity and can withstand frequent use. Investing in a well-built machine ensures that it continues to perform effectively in a busy bakery or kitchen, even under heavy workloads. This helps avoid costly repairs and downtime.

Size and Space Requirements

Choosing the right roller machine depends on your available kitchen space. If you're working with limited space, a compact countertop model might be the best option. These machines save valuable counter space while still offering efficiency. Larger, floor-standing models are suitable for high-volume production environments, offering more robust capabilities for bigger batches. Consider the machine's size and where it will be placed to ensure it fits seamlessly into your workflow.

Speed and Efficiency

Speed is crucial when meeting customer demand, particularly in high-volume production settings. A fast roller machine helps reduce dough preparation time, allowing your kitchen to work more efficiently. Machines with adjustable speed settings can optimize the process, ensuring that dough is rolled out quickly without sacrificing quality. Faster machines are especially beneficial in commercial kitchens where time is of the essence.

Ease of Maintenance

To keep a dough roller machine working at its best, regular maintenance is key. Machines should be easy to clean and maintain to ensure optimal performance. Regular cleaning prevents dough build-up, which can affect the machine's functionality. Following the manufacturer's maintenance recommendations, such as lubricating parts and inspecting for wear, will help extend the machine's lifespan and keep it running smoothly.

How to Choose the Right Roller Machine for Dough

Factors to Consider When Buying a Dough Roller Machine

When selecting a dough roller machine, consider several key factors:

● Production Volume and Batch Size: If you run a high-volume bakery or commercial kitchen, look for machines designed for large batches. Smaller operations might do fine with a compact machine for limited production.

● Kitchen Space and Layout: Measure your kitchen to ensure the roller machine fits. Countertop models are ideal for smaller kitchens, while floor-standing machines are better for spacious areas.

● Budget and Long-Term ROI: While high-quality machines may require a larger upfront investment, they offer better durability and efficiency. Consider how the machine will impact your costs in the long run, including labor savings and increased production.

Manual vs. Automatic Dough Rollers

● Which Type is Right for You?: The right type depends on your business size and production demands. Manual rollers are best for small operations, while automatic models suit high-volume businesses.

● Pros and Cons:

○ Manual Rollers: These are cheaper and give more control, but they require more labor and time, making them ideal for smaller kitchens.

○ Automatic Rollers: Faster and more efficient, these machines are great for large bakeries. They reduce manual labor but come with a higher price tag.

Conclusion

Roller machines for dough offer key benefits like saving time, improving consistency, and enhancing product quality. By ensuring uniform dough thickness, they elevate baking results. Investing in the right machine boosts efficiency and consistency, making your production smoother. Consider your kitchen's size, production volume, and budget before purchasing a roller machine to find the perfect fit.

JINKEJXIE has years of experience in production of Dough Machine. Therefore, If you have any questions about Dough Roller Machine, feel free to contact us anytime with your inguiries.

FAQ

Q: Can I use a dough roller machine for pizza dough?

A: Yes, dough roller machines are ideal for pizza dough. They ensure uniform thickness, which is essential for consistent pizza crusts. The adjustable settings allow you to customize the thickness to suit your needs.

Q: How long does a roller machine last?

A: The lifespan of a dough roller machine depends on its build quality and frequency of use. High-quality models can last many years with proper maintenance, typically ranging from 5 to 10 years.

Q: How do I know if I need an automatic or manual machine?

A: Choose a manual machine for smaller operations or more control. An automatic machine is ideal for high-volume production, offering greater speed and efficiency.

Q: Are roller machines easy to clean?

A: Yes, roller machines are easy to clean. Regular maintenance, such as wiping down surfaces and removing dough residue, helps keep the machine in good condition for long-term use.