Bakers know the struggle of manual dough preparation—it's time-consuming and labor-intensive. But automation is changing the game in commercial baking. The roller dough machine is now a must-have tool for streamlining dough handling and boosting efficiency. In this post, we'll explore how this machine saves time, improves consistency, and helps bakers work smarter, not harder.

What is a Roller Dough Machine?

A roller dough machine is an essential tool in many bakeries, designed to flatten and shape dough quickly and evenly. This machine helps save time by automating the dough rolling process, which would otherwise require a lot of manual effort. It replaces manual rolling, increasing production speed while ensuring consistent thickness and quality with every batch. Additionally, it promotes better hygiene by reducing direct contact with the dough. After mixing, the dough is fed through the roller, ensuring it's properly flattened and ready for the next steps in the baking process.

How Roller Dough Machines Streamline Dough Preparation

Speeding Up the Process

Roller dough machines can roll large volumes of dough in just minutes, which significantly reduces the time spent on dough preparation. This is especially important in high-volume bakeries, where speed is crucial to keeping up with demand. With the machine handling the bulk of the rolling, bakers can focus on other important tasks, increasing overall productivity.

Ensuring Uniform Dough Thickness

These machines provide consistent thickness with every pass, which is essential for maintaining even baking. Whether it's pizza dough, pastry, or bread, uniform dough thickness ensures that every product bakes evenly. This consistency not only improves the final product's quality but also minimizes the risk of undercooked or overcooked areas, delivering perfect results every time.

Reducing Manual Labor and Errors

By automating the rolling process, roller dough machines reduce the need for skilled hand-rolling. This not only saves time but also eliminates the errors that can arise from inconsistent handwork. Even less experienced staff can operate the machine effectively, maintaining quality without needing specialized training. As a result, labor costs are reduced, and production runs more smoothly.

Minimizing Dough Waste

Roller dough machines offer precise portion control and shaping, ensuring that the dough is evenly divided and shaped, reducing waste. This means that less dough is discarded, leading to better cost efficiency. Additionally, by maximizing the use of dough, bakeries can reduce their material costs and increase profitability while being more environmentally friendly by minimizing waste.

Roller Dough Machine vs. Traditional Dough Handling

Labor Intensity

Traditional hand-rolling requires significant effort, especially for large batches. It depends heavily on skilled labor, which can lead to fatigue and inconsistency. Roller dough machines, on the other hand, automate the process, reducing manual labor and allowing bakeries to handle more dough with less physical strain.

Time Efficiency

Manual rolling can be slow, especially when preparing dough in bulk. It takes time to achieve the right thickness, and each batch can be inconsistent. A roller dough machine speeds up the process, rolling dough quickly and evenly for every batch, increasing overall productivity per shift.

Dough Quality

Human hands can create inconsistencies in dough thickness, leading to uneven results. This can affect baking times and the final product. Roller dough machines provide mechanical uniformity, ensuring dough is consistently flattened to the exact thickness needed, resulting in more reliable and higher-quality baked goods.

Key Features that Enhance Workflow

Adjustable Rollers

One of the standout features of roller dough machines is the adjustable rollers. These allow bakers to control the dough's thickness, whether it's for thin pizza crusts, delicate pastry, or thick bread dough. The ability to fine-tune the thickness ensures that each product is made to the desired specifications, which improves consistency and quality across batches.

Compact, Bench-Top or Floor-Standing Designs

Roller dough machines come in various sizes, from compact bench-top models ideal for small bakeries or home kitchens, to larger, floor-standing machines for high-volume commercial operations. This flexibility allows bakeries of all sizes to optimize their space while still benefiting from automated dough rolling. Whether you're running a micro-bakery or a large-scale production line, there's a machine to meet your needs.

Easy-to-Clean Surfaces

Machines with easy-to-clean surfaces are a huge time-saver. After every use, dough and flour can build up, so having a machine that can be cleaned quickly and effectively is essential. Easy-to-clean designs help prevent dough buildup, ensuring the machine stays hygienic and ready for the next batch. This reduces downtime for cleaning and helps maintain a quicker, more efficient production cycle.

Safety and Automation Features

Safety and automation are critical in any bakery setting. Many roller dough machines feature hands-free rolling, which helps minimize contact between the operator and the machine, reducing the risk of injury. Additionally, automatic stop features ensure that the machine halts if something goes wrong, preventing accidents and improving overall safety. These automated features streamline operations, allowing bakers to focus on other tasks while the machine handles the rolling process.

Use Cases – How Bakers Benefit Daily

Artisan Bakeries

In artisan bakeries, where quality and hand-feel are key, roller dough machines provide machine-level efficiency while preserving the craft. Bakers can achieve consistent dough thickness without losing the texture and feel that define artisan products.

Pastry Chefs

For pastry chefs, precision is everything. Roller dough machines make perfect dough sheets for croissants, puff pastry, and other delicate items. The machine ensures even thickness, which is crucial for layers to rise perfectly and maintain their texture.

Pizza Makers

Pizza makers benefit from the speed and consistency a roller dough machine provides. High-volume pizza bases can be made quickly, ensuring that each pizza crust is the same thickness for even cooking. This increases output and helps meet the demands of busy pizza shops.

Commercial Production Lines

In large-scale commercial bakeries, roller dough machines fit seamlessly into continuous production lines. They help streamline the dough preparation process, integrating smoothly into automated workflows, allowing for faster and more efficient mass production.

Types of Roller Dough Machines for Different Bakery Sizes

Manual Roller Machines

Manual roller machines are ideal for home bakers or small micro-bakeries. They're simple, cost-effective, and compact, perfect for low-volume production. These machines are operated by hand, giving the baker complete control over the rolling process, making them a great choice for small-scale operations.

Semi-Automatic Models

Semi-automatic roller dough machines are designed for small to medium-sized bakeries that require a moderate output. These machines combine manual input with automated features, allowing for faster dough rolling without sacrificing control. They are perfect for bakeries looking to increase production without the full automation of larger systems.

Fully Automatic Roller Dough Machines

Fully automatic roller dough machines are designed for high-speed industrial operations. These machines can handle large volumes of dough, operating without much manual intervention. Ideal for large commercial bakeries, they integrate seamlessly into automated production lines, increasing output while maintaining consistent dough quality.

Key Considerations Before Purchasing

Production Volume Needs

When selecting a roller dough machine, it's important to consider how much dough you'll need to process daily. Smaller bakeries may only require a manual or semi-automatic model, while larger operations may need a fully automatic machine to handle high volumes efficiently.

Dough Types (High-hydration, sticky, etc.)

Different dough types, such as high-hydration or sticky dough, may require specialized machines. Make sure the roller dough machine you choose is capable of handling the specific dough types you use most frequently, ensuring smooth and consistent results.

Power Supply and Space Constraints

Check the machine's power requirements and ensure that your bakery has the appropriate setup. Additionally, consider the space available in your kitchen or production area. Compact models are ideal for smaller bakeries, while larger machines might need more floor space in high-production environments.

Budget vs ROI – Value Over Time

Purchasing a roller dough machine involves an upfront cost, so it's important to weigh the price against long-term savings. While higher-end models may be more expensive initially, they can offer greater efficiency, speed, and durability, ultimately delivering better value and a higher return on investment over time.

Conclusion

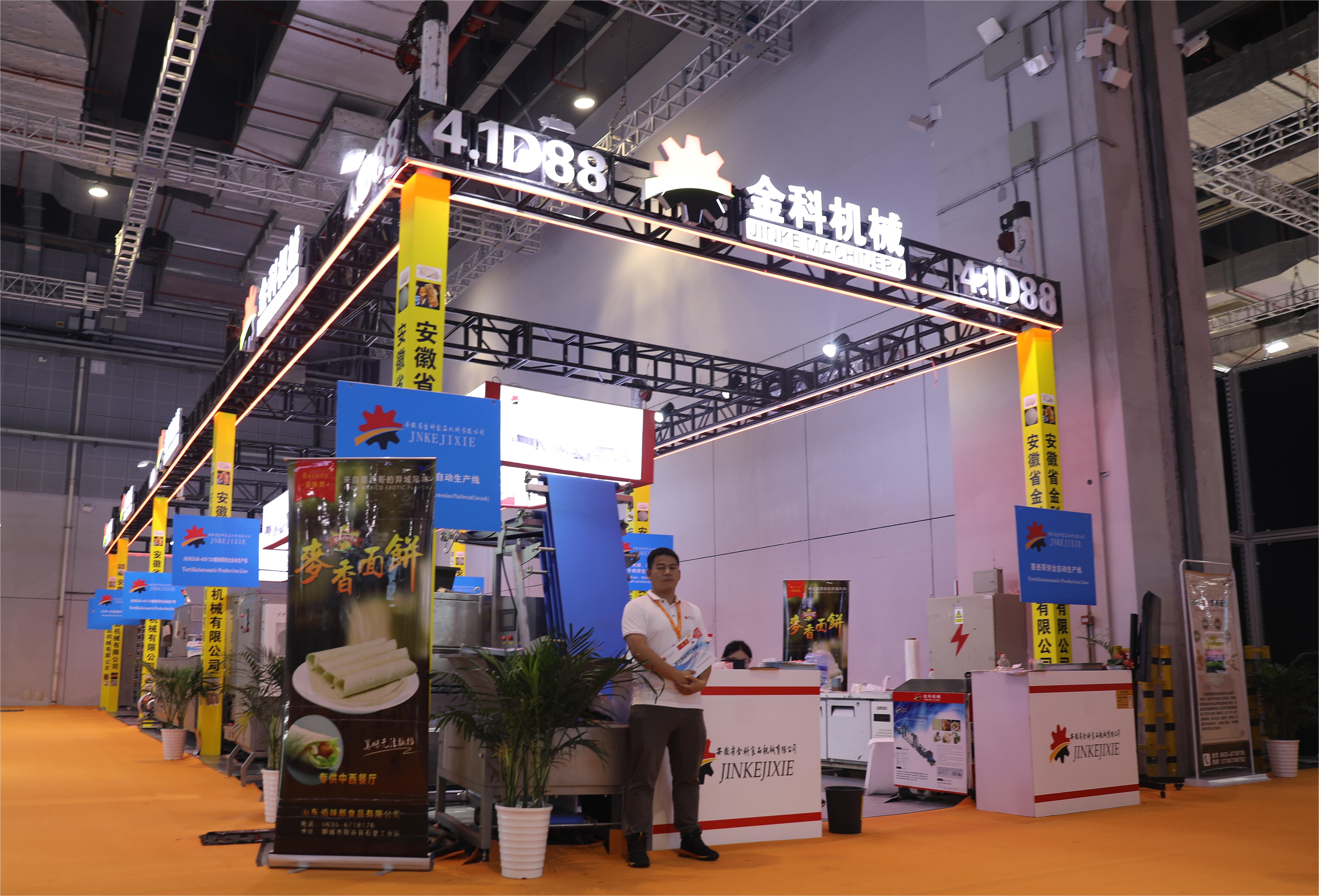

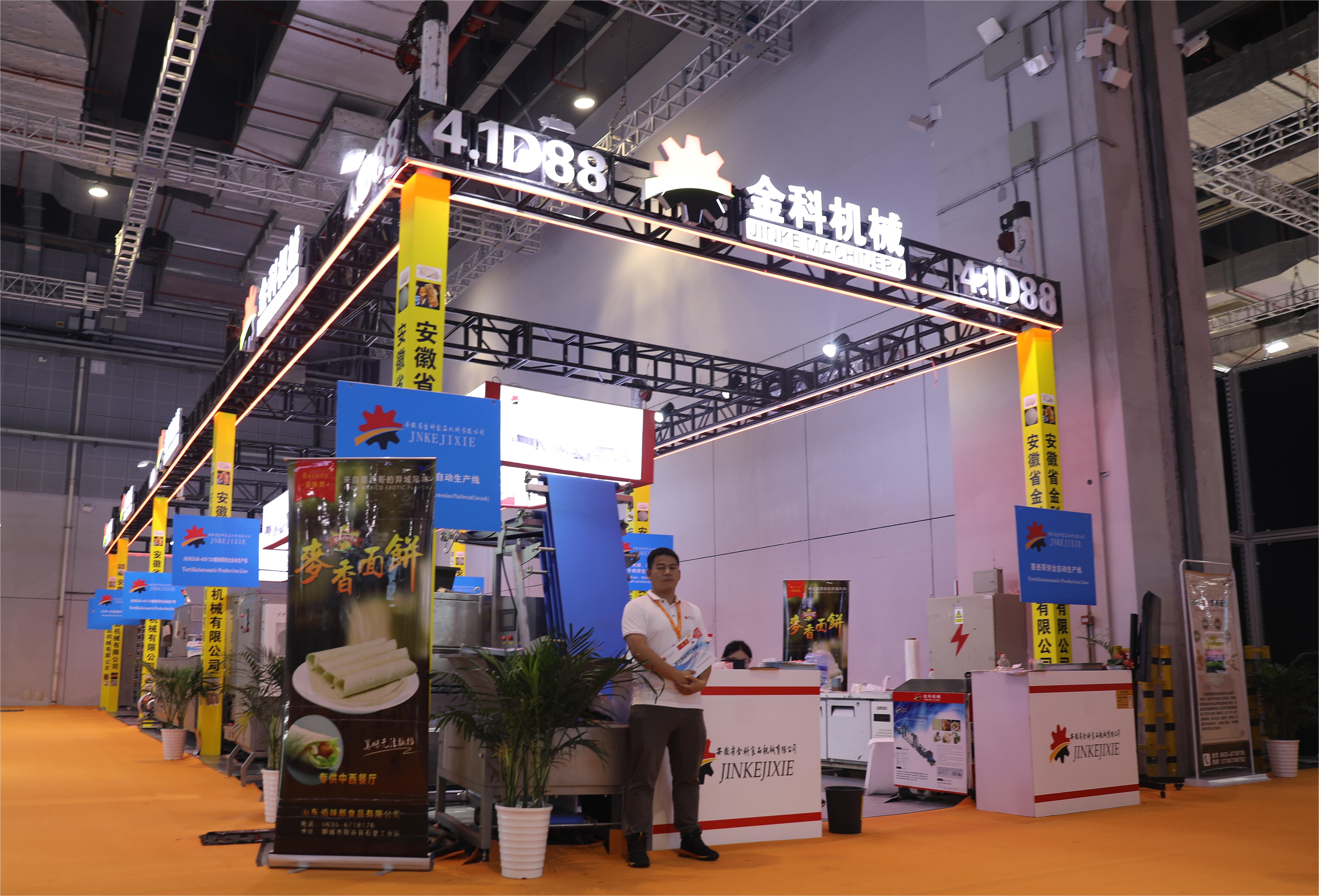

Roller dough machines save time, reduce waste, and improve dough consistency, enhancing the quality of baked goods. These machines boost efficiency, making production faster and more reliable. Over time, the investment pays off by improving business growth and profitability. If you're looking to streamline your bakery operations, exploring roller dough machine options is a smart choice. Welcome to JINKEJIXIE Consulting Products!

FAQ

Q: Can a roller dough machine handle laminated dough?

A: Yes, some roller dough machines can handle laminated dough, but it's important to check if the machine is specifically designed for such tasks.

Q: How thin can it roll the dough?

A: Roller dough machines can roll dough to a thickness as thin as 1mm, depending on the model.

Q: Is it safe for continuous use?

A: Many roller dough machines are designed for continuous use, especially in commercial settings, with features like automatic stop for safety.

Q: What types of dough are best suited for roller machines?

A: Roller dough machines are ideal for pizza dough, bread, pastry, and other soft dough types.

Q: How does it compare to a dough sheeter?

A: Unlike dough sheeters, roller dough machines are often more versatile, handling a wider variety of doughs with less complexity.