The line is a common industrial food machine, it can quickly complete The dough dividing machine is a common industrial food machine, it can quickly complete dough conveny dough divide other different processes. This article will introduce the relevant knowledge of the automatic food production line for you, and hope to help you.

The characteristics of the automatic food machine production line.(1.Processing,2.Parameters,3.Overview,4.Feature,5.Purpose,6.Operation guide)

1.Processing

Dough conveny dough divide

2.Parameters

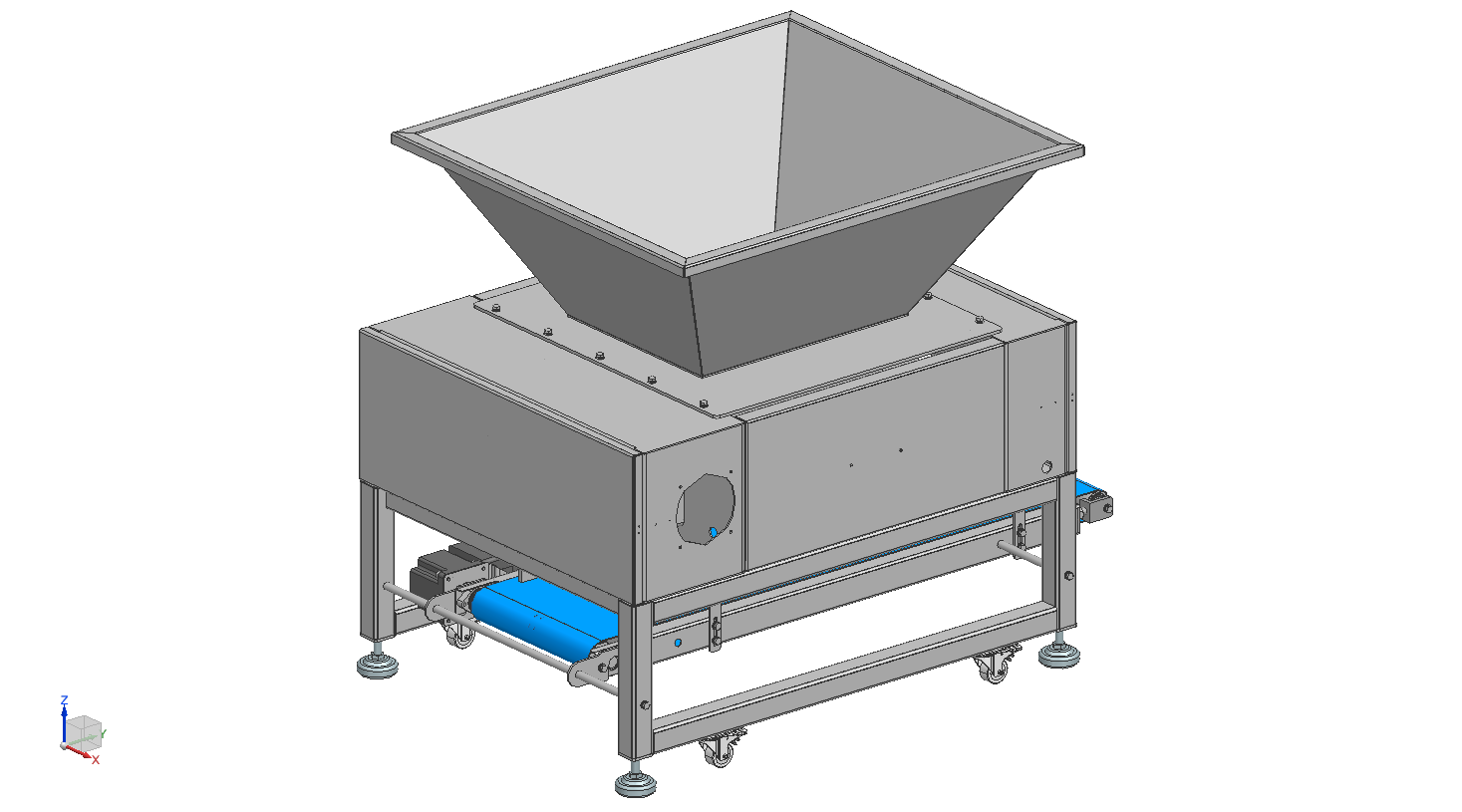

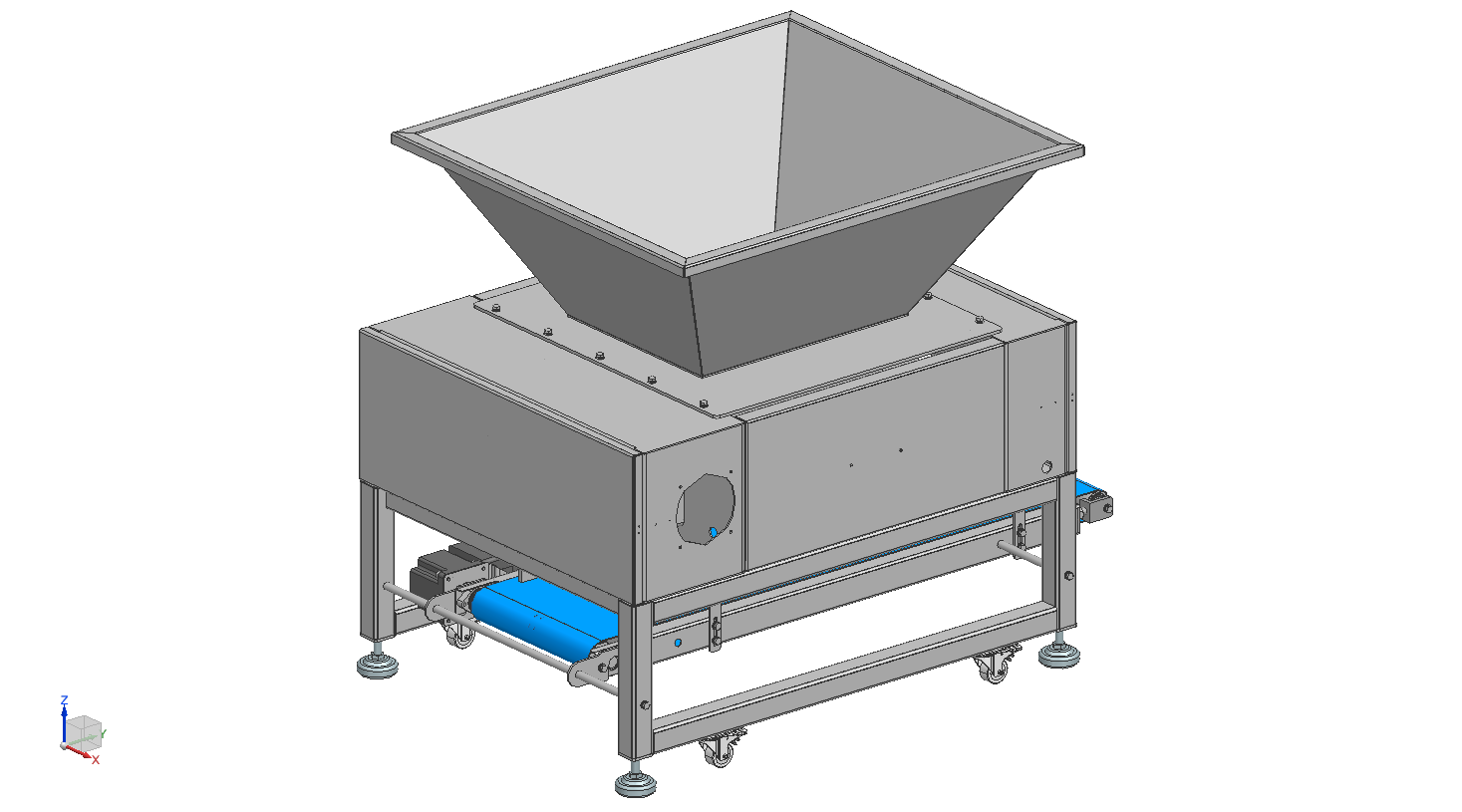

| Model | JKFKJ | Power | 0.95kw |

| Size | 1447*1151*1100 mm | Weight | About 100kg |

3.Overview

Depending on the actual situation of the dough and the customer, the dough can be divided multiple times, or multiple doughs can be divided at the same time.

4.Feature

The food machine adopts PLC and touch screen memory function, and the whole food machine components are made of Delta, Siemens, Mitsubishi, Omron, NSK, etc., to ensure product stability. Simple operation, stable quality, range adjustment, production process automation, compact structure, stable performance, easy maintenance.

5.Purpose

Divide dough

6.Operate Guide(2-3 operators)

One person patrols the line, and another person places the finished product at the end of the production line to complete the entire production process, thus greatly increasing the production efficiency of the enterprise and reducing the production cost of the enterprise.