Baking perfect dough requires consistency, but achieving it can be time-consuming and challenging. A roll dough machine makes this process easier, ensuring uniform thickness quickly and efficiently. In this post, we'll explore how a roll dough machine helps bakers achieve perfect dough consistency with precision and speed.

What is a Roll Dough Machine?

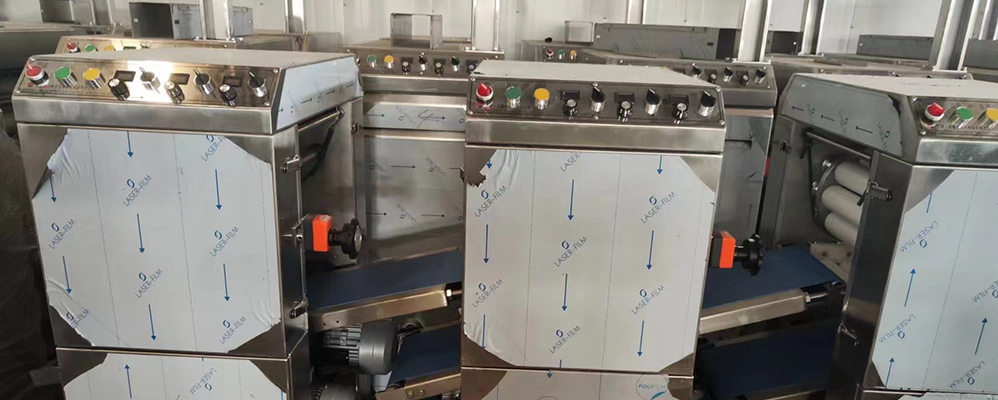

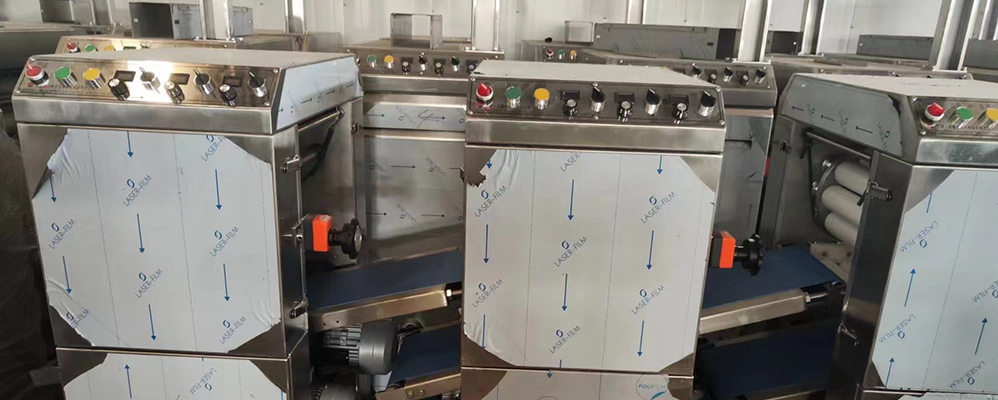

A roll dough machine is an essential piece of equipment in bakeries, designed to roll and flatten dough with precision. It uses rollers to stretch dough evenly, ensuring uniform thickness, which is crucial for baking consistent, high-quality products.

These machines help bakers achieve perfect dough consistency across various baked goods. Whether it's bread, pizza dough, or pastries, the machine ensures that each piece has the same thickness, leading to better texture and even baking.

How Does a Roll Dough Machine Achieve Perfect Dough Consistency?

Adjustable Rollers for Precision

Adjustable rollers are key in ensuring uniform dough thickness. By controlling the gap between rollers, bakers can easily adjust the dough's thickness for different products. Whether making thick bread or thin pizza dough, the rollers ensure that each batch has the same consistent thickness.

The roller gap settings are crucial. They determine how thin or thick the dough becomes, allowing bakers to maintain perfect consistency across all baked goods.

The Feeding System: Ensuring Smooth, Even Dough Flow

The feeding system is designed to guide the dough evenly through the rollers. It ensures the dough flows smoothly, preventing any inconsistencies in thickness. This even movement is essential for getting the right dough consistency.

Automation plays a big role here. It reduces human error by making the process more consistent. The system ensures dough is fed evenly, resulting in uniform thickness every time.

Speed Control: Achieving the Right Thickness with Efficiency

Speed control is vital for achieving the right dough consistency quickly. By adjusting the speed, bakers can ensure that the dough is rolled at the perfect pace, whether it's a delicate dough or a denser one.

Speed adjustments allow the machine to handle different dough types. For example, slower speeds are used for delicate doughs, ensuring they stay intact. Faster speeds are great for denser doughs, making the process more efficient.

The Benefits of Using a Roll Dough Machine for Perfect Dough Consistency

Consistency in Dough Thickness

A roll dough machine ensures precise, uniform dough thickness every time. By adjusting the roller gap settings, the machine can achieve consistent thickness across all dough pieces. This consistency is crucial for even baking, ensuring the dough bakes evenly and achieves the right texture. With perfect dough consistency, the end result is a superior product that looks professional and tastes great.

Increased Efficiency: Save Time While Maintaining Quality

Using a roll dough machine significantly reduces dough preparation time. Instead of spending time manually rolling dough, the machine rolls large amounts quickly and with consistent results. This time-saving advantage allows bakers to focus on other tasks, increasing productivity.

In comparison to manual dough rolling, machines eliminate human errors that lead to uneven thickness. Manual rolling can be slow and tiring, requiring repetitive motions that may lead to inconsistencies in dough. A roll dough machine guarantees faster production while maintaining high-quality standards.

Versatility Across Dough Types

One of the major benefits of a roll dough machine is its versatility. It accommodates various dough types, including bread, pizza, pastries, and more. By adjusting the settings, bakers can easily switch between different doughs without compromising consistency.

Whether you need a thin pizza crust or a thicker loaf of bread, the machine's adjustability ensures that each type of dough is rolled to the ideal thickness, maintaining perfect consistency for each product. This flexibility makes it easier to meet different customer demands and expand product offerings.

Reducing Manual Labor: Consistency Without Fatigue

Manual dough rolling can be physically demanding, leading to fatigue and inconsistent results. A roll dough machine reduces the physical strain on bakers by automating the rolling process, ensuring consistent dough thickness with minimal effort.

The ergonomic design of these machines reduces the risk of repetitive strain injuries, which are common in bakeries where manual labor is extensive. By eliminating the need for manual rolling, the machine promotes a smoother workflow and boosts overall productivity, keeping bakers fresh and reducing physical exhaustion.

Key Features of Roll Dough Machines That Ensure Consistent Results

Adjustable Roller Gaps

Fine adjustments of the roller gaps are essential for controlling dough thickness. By tweaking the gap, bakers can easily achieve precise dough thickness, which is crucial for consistency. Whether making thin pastry dough or thick bread dough, adjusting the rollers helps maintain uniformity across batches.

Non-Stick Rollers for Easy Dough Flow

Non-stick rollers play a significant role in ensuring smooth dough flow. They prevent the dough from sticking to the rollers, which can cause inconsistencies in thickness. With these rollers, dough moves effortlessly through the machine, allowing for continuous and uniform rolling. This feature ensures consistent results from start to finish.

Automated Feeding Systems

Automated feeding systems help guide the dough through the rollers evenly. These systems ensure that the dough flows smoothly without interruptions, preventing any inconsistencies during operation. By automating the feeding process, the machine eliminates human error, contributing to uniform dough consistency across all products.

Digital Controls for Exact Thickness

Digital controls give bakers the ability to maintain precise dough thickness settings. These controls allow for easy adjustments, ensuring that each batch is rolled to the exact specifications required. With digital settings, bakers can achieve perfect consistency every time, making it easier to meet production standards and customer expectations.

Choosing the Right Roll Dough Machine for Consistency

Assess Your Production Needs

When selecting a roll dough machine, it's important to consider the scale of your operation. Small bakeries may need a more compact, cost-effective machine, while larger operations require machines that can handle higher production volumes.

Key factors to consider include the batch size you typically prepare and the types of dough you work with. For example, commercial bakeries may need machines that can handle thicker doughs, while smaller businesses may prioritize versatility for various dough types like pizza, bread, or pastries.

Space and Installation

Before purchasing a roll dough machine, ensure your bakery has enough space to accommodate it. These machines can vary in size, so it's crucial to measure the available space and ensure it fits into your workflow without causing disruptions. Consider both the machine’s footprint and height to avoid overcrowding your kitchen or production area.

Budget and Investment

Choosing the right machine also involves balancing your initial investment with long-term benefits. A high-quality roll dough machine may have a higher upfront cost but can provide significant savings in time and labor. It also improves dough consistency, reducing waste and helping you maintain product quality over time. Think of it as a smart investment for long-term efficiency and consistent results.

Roll Dough Machine Maintenance for Consistent Performance

Daily and Weekly Care

Regular cleaning and maintenance are essential to keeping your roll dough machine running smoothly. Clean the rollers and feeding system after each use to prevent dough buildup, which can affect performance. Use a damp cloth and mild soap to wipe down surfaces, and always dry thoroughly to prevent rust.

For weekly maintenance, inspect the belts for wear and check the rollers for any buildup that might impact dough consistency. Regularly lubricate moving parts as recommended by the manufacturer to maintain smooth operation.

Troubleshooting Common Issues Affecting Dough Consistency

Sometimes, your roll dough machine may encounter issues that affect dough consistency. If the dough thickness is uneven, it could be due to misaligned rollers or an issue with the feeding system. Adjust the roller gaps or check for blockages in the dough flow path.

Motor malfunctions can also cause inconsistencies. If the machine is running slowly or inconsistently, ensure the motor is functioning correctly and that electrical connections are secure. Always refer to the user manual for troubleshooting steps.

Long-Term Care for Continued Precision

Long-term care is key to maintaining your roll dough machine's performance. Make sure to follow a regular maintenance schedule, including checking for any wear and tear on parts like belts or rollers.

Keeping the machine clean and regularly serviced will ensure it continues to deliver precise, consistent results for years. Proper maintenance extends the life of the machine and helps preserve dough quality over time.

Conclusion

A roll dough machine ensures consistent dough thickness, improving your baking results. It helps maintain uniformity and texture across different baked goods. Investing in a high-quality roll dough machine is essential for increasing efficiency, product quality, and consistency in your bakery. It’s a key investment for long-term success. Welcome to JINKEJIXIE Consulting Products!

FAQ

Q: How do I adjust the dough thickness for different baked goods?

A: Adjust the roller gap settings to control dough thickness. The machine can be customized to meet different dough requirements.

Q: What maintenance is required to ensure consistent results?

A: Regular cleaning, lubrication, and checking for wear on belts and rollers are essential. Weekly checks and proper care extend the machine's lifespan.

Q: Can I use a roll dough machine at home?

A: Yes, there are compact models available for home use. They offer the same benefits of consistency and efficiency.

Q: How does a roll dough machine compare to hand-rolling in terms of consistency?

A: A roll dough machine provides more consistent results, with uniform thickness and reduced human error, unlike manual rolling.