For centuries, Parotta, the flaky, layered flatbread beloved across South India and Sri Lanka, has been crafted by hand. The rhythmic folding, stretching, and flipping of dough—once a purely manual art—defines the bread’s signature texture. But as global demand for South Asian cuisine rises and the food industry evolves toward efficiency and consistency, automation has entered the scene.

Modern Parotta production lines are redefining how this traditional flatbread is made, combining centuries-old recipes with advanced engineering.

1. Understanding the Essence of Parotta

Before diving into automation, it’s worth understanding what makes Parotta unique. Unlike ordinary flatbreads such as roti or naan, Parotta is layered, flaky, and buttery, often made with refined wheat flour (maida), oil, and water. The secret lies in the kneading and layering technique—stretching the dough thinly, folding it repeatedly, and cooking it to achieve a soft yet crisp texture.

Traditionally, skilled artisans spent years perfecting this craft. Each Parotta was manually shaped, layered, and roasted on a griddle. While this process yielded unmatched flavor, it was time-consuming, inconsistent, and labor-intensive—especially in large-scale food production.

2. The Rise of Automation in Parotta Making

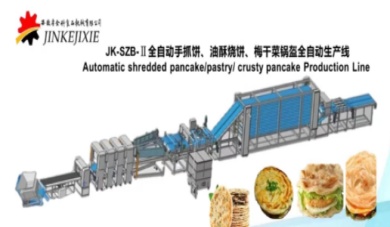

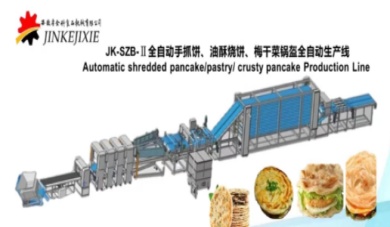

The shift toward automation began as restaurants, hotels, and food suppliers sought to meet higher production volumes without compromising quality. Manufacturers like AnHui JinKe Foodstuff Machinery Co., Ltd. have pioneered advanced Parotta production lines that replicate the manual process with precision and reliability.

Automation has introduced several key advantages:

Uniform quality: Machines ensure consistent thickness, texture, and size.

Labor efficiency: Reduces dependence on skilled manual labor.

Hygiene: Fully enclosed, stainless-steel systems minimize contamination risks.

Scalability: Production can increase from hundreds to thousands of Parottas per hour.

3. Step-by-Step Breakdown: How a Parotta Production Line Works

A modern Parotta production line seamlessly integrates traditional craftsmanship with advanced automation. Each stage mirrors the manual process once performed by skilled hands—but with precision, hygiene, and consistency on an industrial scale. Below is a detailed look at each step in this automated journey from dough to delicious Parotta.

Step 1: Dough Preparation and Mixing

Every perfect Parotta begins with high-quality dough. In an automated production line, this process starts in an industrial dough mixer, where carefully measured quantities of flour, water, salt, and oil are combined under precisely controlled temperature and timing conditions.

Advanced mixing systems incorporate several intelligent features:

Automatic ingredient dosing ensures accurate proportions every time, reducing human error and material waste.

Vacuum kneading technology improves gluten development, giving the dough its ideal elasticity and texture.

Temperature monitoring prevents overheating, maintaining the integrity and hydration of the dough.

This combination results in a smooth, pliable, and homogeneous dough that forms the foundation for consistent Parotta production. Once the dough is ready, it moves automatically to the next stage without manual handling, preserving both hygiene and efficiency.

Step 2: Dough Resting and Portioning

Resting the dough is a crucial step for gluten relaxation and better texture. In traditional preparation, this step required time and space. Modern Parotta lines solve this with dough resting conveyors or controlled holding chambers, where the dough rests under optimal humidity and temperature conditions.

Once the resting phase is complete, the dough travels to an automatic portioning machine. Here, precise sensors and weighing systems divide it into uniform balls, each matching exact weight specifications. This ensures consistent size, shape, and product yield, which is essential for both quality assurance and production cost control.

Some high-capacity lines also feature inline oiling systems, preventing dough pieces from sticking during handling and maintaining surface flexibility for later stages.

Step 3: Sheeting and Layering

The signature texture of Parotta comes from its delicate, multi-layered structure. Traditionally, cooks achieved this by stretching dough balls into paper-thin sheets, brushing them with oil, and folding them multiple times by hand.

Modern Parotta production lines replicate this artistry through automated sheeters and stretchers:

Dough balls are pressed into uniformly thin sheets using precision rollers.

Automatic oil sprayers apply a fine, even layer of oil or shortening across the surface.

A mechanical folding system repeats the stretch-fold process multiple times to create the signature flaky layers.

High-end machines allow operators to customize parameters such as the number of folds, sheet thickness, and oil ratio—enabling the production of different Parotta types, from soft Malabar Parottas to crispy street-style versions.

The outcome is a consistent, layered dough that’s ready for shaping.

Step 4: Coiling and Shaping

Once layered, the dough must be shaped into its recognizable spiral form. Traditionally, this involved manual coiling by hand. In modern production, this is achieved through a coiling and pressing module that performs the same action with speed and precision.

The dough sheet is automatically coiled into tight spirals and lightly pressed to form round discs. The roller pressure and pressing duration can be adjusted to achieve different diameters and thicknesses. This ensures that every Parotta maintains uniform dimensions, crucial for even cooking and visual appeal.

Automated shaping not only improves consistency but also drastically reduces production time—turning what once took several minutes per piece into a matter of seconds.

Step 5: Baking or Pre-Cooking

Depending on production goals, Parottas can be partially baked (ideal for freezing and later reheating) or fully cooked. Automated baking tunnels or conveyor griddles handle this stage with remarkable control.

Key innovations include:

Infrared or induction heating systems, which provide rapid, even heat transfer and energy efficiency.

Temperature zoning technology, which mimics traditional griddle conditions—initial high heat for browning followed by gentle warmth for complete cooking.

Real-time feedback sensors, ensuring each Parotta achieves uniform color, texture, and moisture levels.

This step develops the golden, flaky surface and initial crispness while preserving inner softness, ensuring the final product tastes just like its handmade counterpart.

Step 6: Cooling and Packaging

Immediately after baking, Parottas move along a cooling conveyor system that gradually lowers their temperature. Controlled cooling prevents condensation, which could otherwise lead to sogginess or microbial growth.

Once cooled, the Parottas enter the automatic packaging unit, a vital part of maintaining product hygiene and shelf life. Modern systems perform multiple functions:

Nitrogen flushing to prevent oxidation and preserve freshness.

Vacuum sealing for export-ready packaging and long-term storage.

Batch coding and labeling for traceability and compliance with food safety standards.

In advanced lines, packaging speed and material type can be customized—allowing seamless integration with frozen, ready-to-eat, or retail packaging operations.

The final product is clean, consistent, and ready for storage or shipment, maintaining its freshness and authentic flavor for extended periods.

4. Automation vs. Tradition: Maintaining Authenticity

A common question among chefs and food manufacturers is whether automated Parotta production can truly replicate the handmade version. The answer lies in machine precision and process customization.

Leading manufacturers have designed Parotta lines that mimic the stretch-fold-coil motions of human hands, ensuring authentic texture. Temperature and timing controls preserve the delicate layering that gives Parotta its signature bite.

In fact, automation not only maintains authenticity but also enhances it—by eliminating inconsistencies caused by fatigue, human error, or environmental factors like humidity.

5. Energy and Resource Efficiency

Beyond speed and uniformity, today’s Parotta production lines focus on sustainability. Intelligent systems use energy-efficient motors, optimized conveyor speeds, and recycled heat to reduce energy consumption.

Ingredient waste is minimized through precise portioning and oil application controls. Some systems even reclaim excess oil for reuse, reducing both cost and environmental impact.

These advances make modern Parotta production not only efficient but also eco-conscious—a critical factor for food companies committed to sustainability.

6. Applications and Market Advantages

Automated Parotta production lines serve a broad range of businesses:

Frozen food manufacturers producing ready-to-heat Parottas.

Restaurants and caterers looking for consistent supply.

Export companies shipping large quantities to international markets.

Retail brands creating branded frozen Parotta products.

The scalability and flexibility of these lines allow producers to meet local and global demand with minimal downtime. With adjustable parameters, manufacturers can also diversify products—offering plain, stuffed, or layered Parottas from the same system.

7. The Future of Parotta Production: Smart Automation and AI Integration

As food manufacturing evolves, so does automation. The next generation of Parotta production lines is expected to incorporate AI-based quality control and IoT connectivity for predictive maintenance and data tracking.

Imagine a system that automatically adjusts dough hydration based on humidity levels or predicts when a roller needs maintenance—reducing downtime and improving product consistency even further.

Such innovations are paving the way for Industry 4.0 in food manufacturing, blending tradition and technology more seamlessly than ever before.

8. Conclusion: Tradition Preserved Through Technology

The Parotta production line is more than just machinery—it’s a bridge between cultural heritage and industrial innovation. Automation allows manufacturers to deliver authentic, high-quality Parottas at scale, preserving the taste of tradition while meeting modern demands for hygiene, speed, and consistency.

Companies like AnHui JinKe Foodstuff Machinery Co., Ltd. are at the forefront of this transformation, developing systems that combine mechanical precision with culinary authenticity. Whether you’re a restaurant owner, food manufacturer, or distributor, exploring these solutions can open new possibilities in efficiency and product quality.

To learn more about advanced Parotta production lines and how automation can elevate your flatbread business, visit AnHui JinKe Foodstuff Machinery Co., Ltd. or contact their team for detailed product information and technical support.